The Benefits of Conducting Regular Inventory Counts for Your Business

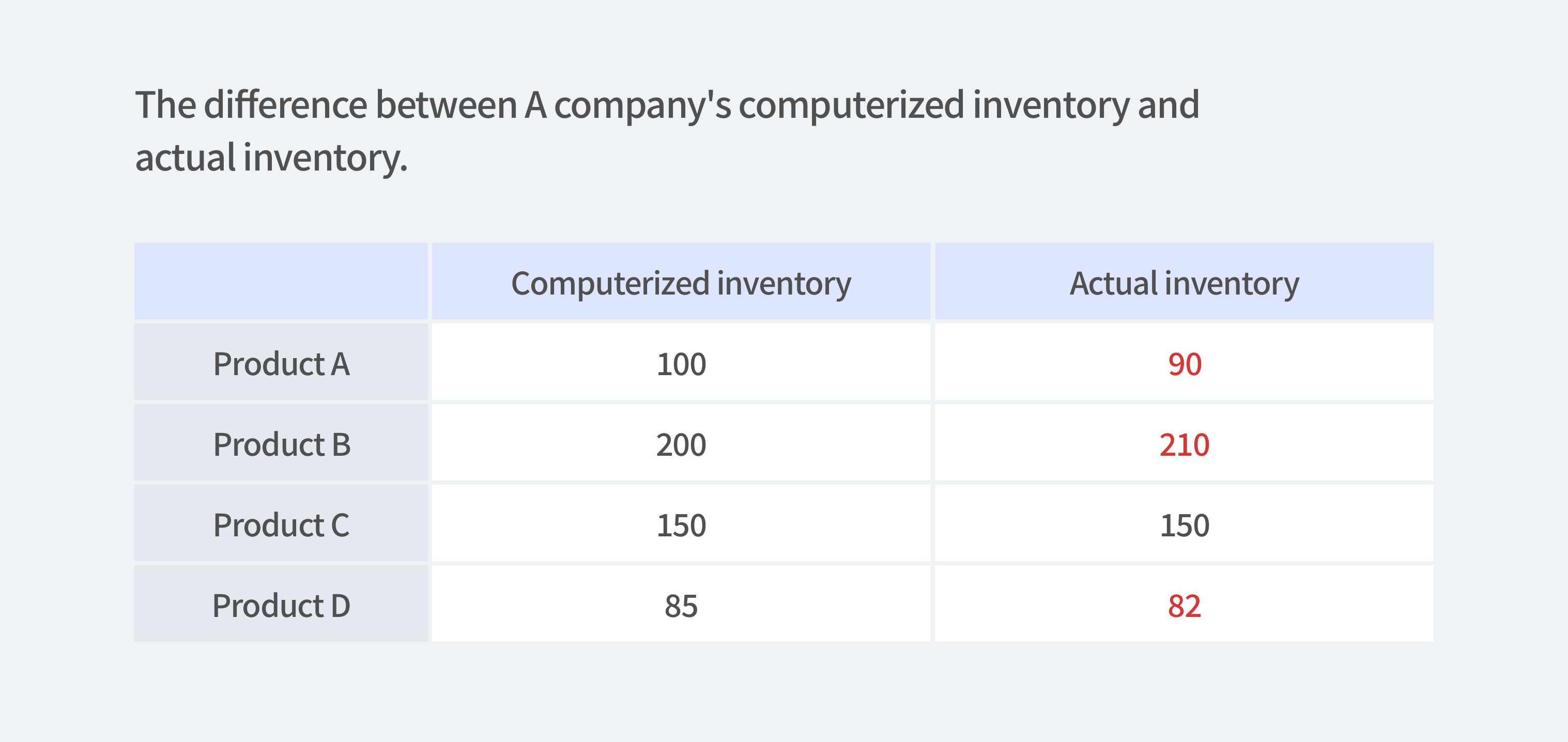

There is a discrepancy between the inventory recorded in the system and the actual inventory held in the warehouse. Company A discovered this through inventory counts, which is the process of verifying the accuracy of the quantity of physical inventory against the system-recorded inventory. It involves physically counting the items stored in the warehouse.

Regular inventory counts are crucial for proper inventory management, and many companies perform them on a monthly, quarterly, or semi-annual basis. Inventory counts are also essential for corporate year-end financial statements, thus many companies conduct the counting, especially during the year-end season.

3 Benefits of Conducting Regular Inventory Counts

1. Accurately track inventory

Discrepancies between physical inventory and system-recorded inventory can cause a variety of issues. For example, a company may receive an order for 100 units of Product A. The sales team checks the system-recorded inventory, which indicates that there are 100 units of Product A, and promises to deliver the order on time. However, the actual inventory in the warehouse is only 90 units of Product A. As a result, the company fails to meet the delivery deadline and undermines the customer's trust. In response, the company may increase safety stock, resulting in increased inventory costs.

Therefore, it is essential to conduct regular inventory counts to ensure consistency between physical and system-recorded inventory. Regular inventory counts allow businesses to respond promptly to customer demands, manage inventory rationally, and lower inventory costs.

2. Identify inventory loss resulting from damage, theft, or malfunction

I am a very meticulous person, thus confident that my physical inventory and system-recorded inventory match perfectly. Do I still have to conduct inventory counting regularly?

The answer is a definite yes! Unforeseen losses such as damages, theft, or malfunctions can occur over time, resulting in inventory shrinkage. These losses, also known as shrinkage, can be detected through periodic inventory counts. Early identification of losses enables the prevention of further losses, and disposing of abnormal inventory ensures sufficient warehouse space.

3. Organize unattended items for a long period of time

Inventory is directly linked to the costs of a company. Stockpiling items that have no demand is a shortcut to wasting procurement, storage, and management costs. Conducting inventory counts is an excellent opportunity to visually inspect and organize items that have not been shipped from the warehouse for a long time. Although you can verify inventory levels by computer, it is more reliable to witness dusty items with your own eyes. Inventory counting can serve as a turning point to reassess purchasing plans when the business consistently purchases items that have not been shipped.

The Typical Procedure of Inventory Counting

Inventory counting is typically performed through the following procedure:

2. Distribute inventory count tags.

3. Staffs count inventory in the warehouse.

4. Staffs return inventory count tags to the manager.

5. Find discrepancies.

6. Re-count.

7. Reconcile and finalize the inventory report.

8. Input the final inventory level on the system (e.g. Excel).

Carrying physical inventory lists or tags that display item information and system inventory, manually recording the actual inventory quantity, and subsequently recording data into inventory management software such as Excel.

The aforementioned inventory counting method requires significant manual effort and presents several challenges, including the potential for human error during 1) individual counting, 2) transferring manual records to inventory management files, and 3) difficulty distinguishing visually similar items.

Excessive errors in inventory counting can render the process meaningless in terms of ensuring accurate inventory management. Similarly, allocating excessive time to inventory counting to minimize errors is not an efficient inventory management strategy. Is there a solution?

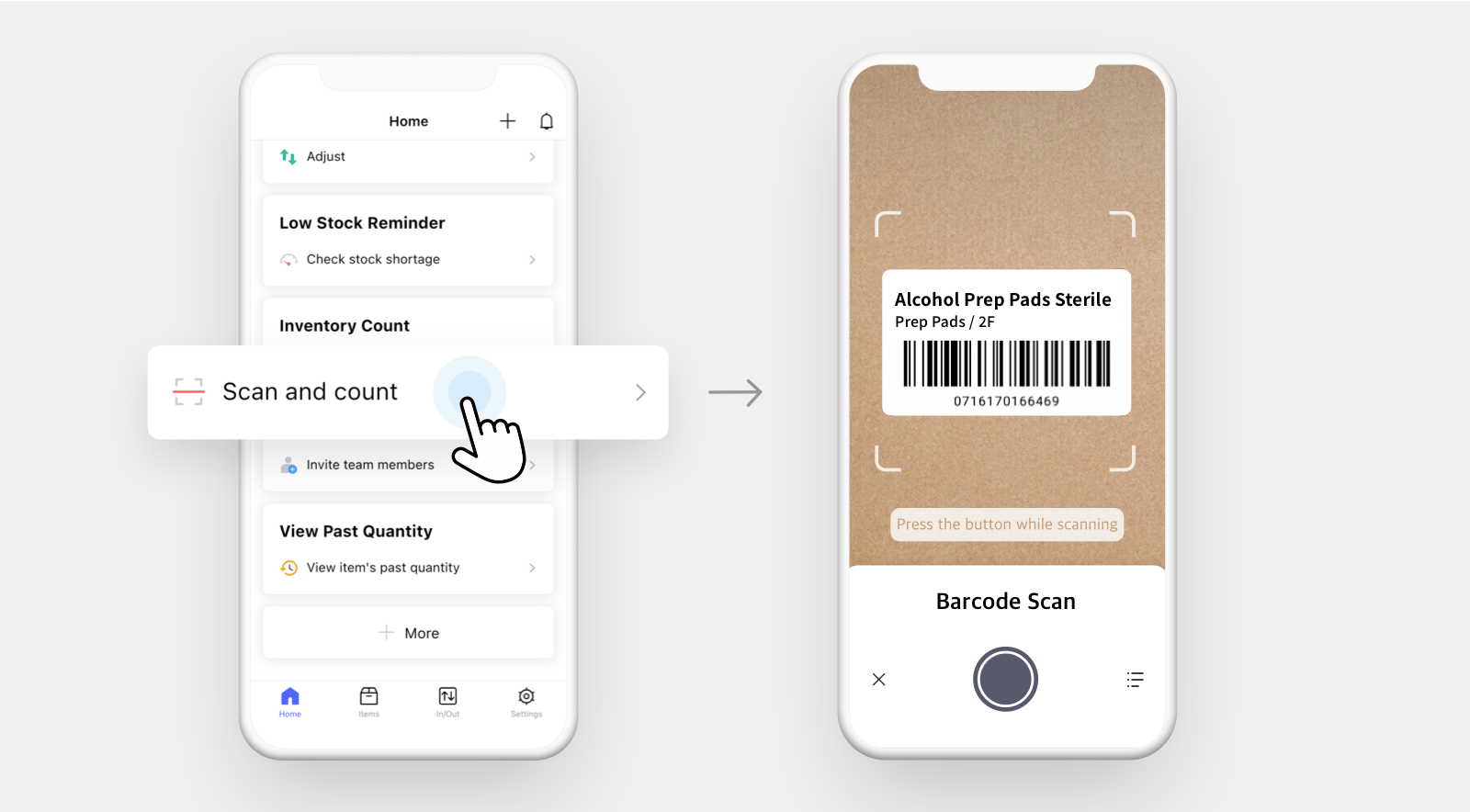

Inventory Counting Feature in BoxHero

With BoxHero, an inventory management solution, you can perform inventory counts easily and efficiently without any errors or mistakes. By using the mobile app installed on your smartphone, you can conduct inventory counts without the need to carry inventory sheets and transfer records manually. In addition, you can scan barcodes using the in-app camera, eliminating the possibility of human errors when counting each item individually.

Inventory Counting Procedure on BoxHero

- Click

Inventory Countingon BoxHero. - Select the warehouse location if you have multiple warehouses.

- Start scanning the barcodes of inventory with the in-app camera.

- Check the latest inventory level by clicking

List icon. - Finish by clicking the

[location name] Completedbutton.

Done will record all unscanned items as '0'.When conducting inventory counting using the BoxHero, inventory management solution, all inconveniences that may occur during the conventional process can be resolved.

- BoxHero's in-app camera allows you to scan barcodes individually for each item, eliminating manual counting errors.

- BoxHero automatically updates inventory counts to match scanned physical inventory quantities, avoiding errors caused by manually recorded data transferred to inventory management files.

- Scanning unique barcodes for each item on BoxHero eliminates errors that may occur due to difficulty in distinguishing between similar-looking items with the naked eye.

To simplify the inventory counting procedure and achieve rational inventory management, try the hassle-free BoxHero inventory counting feature. Give it a try and decide later!